Humidity Sensor - Transmitter - Tranducer skSATO

Correcting Humidity Measurement Errors in AHU

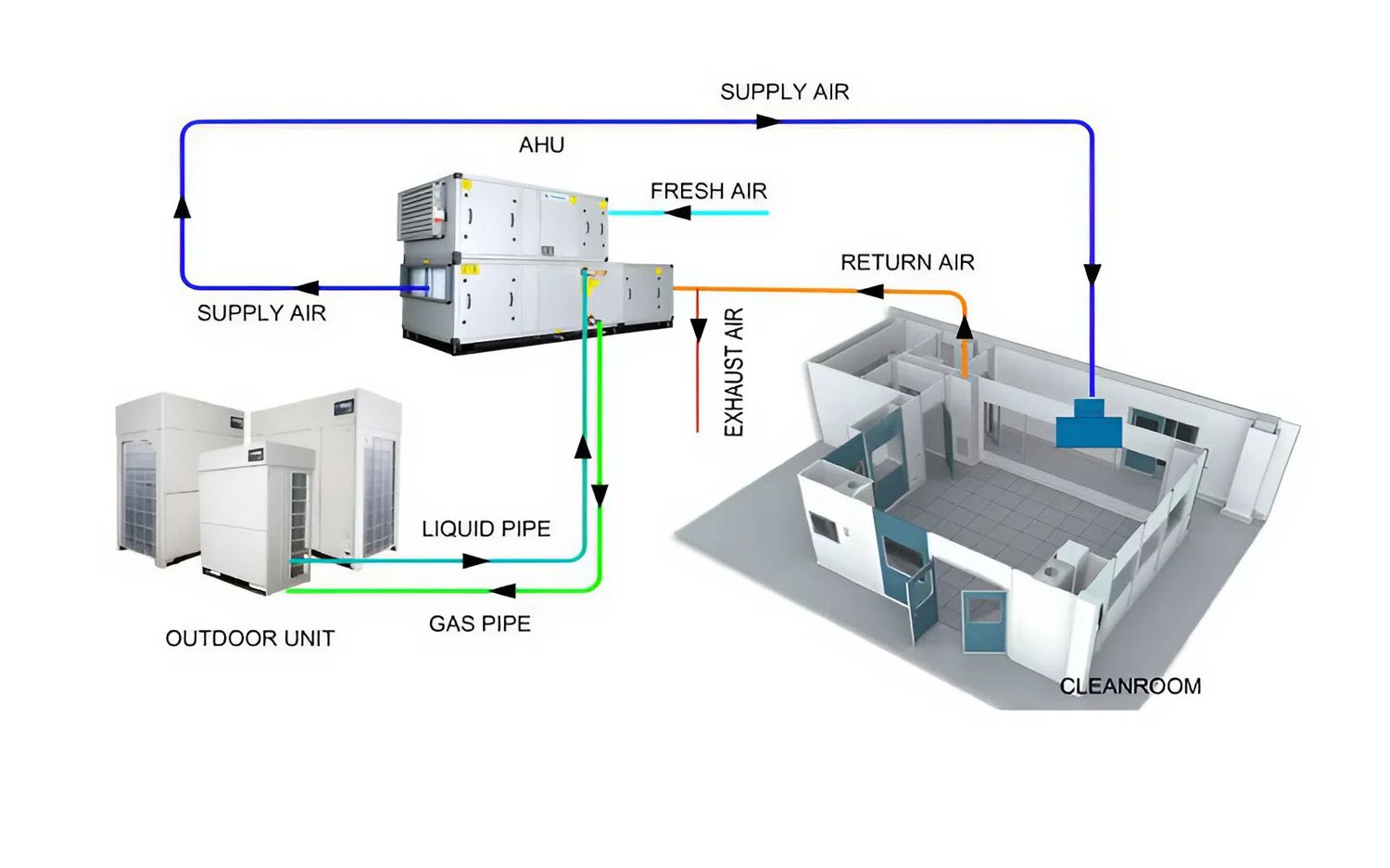

Maintaining humidity within the specified range in a central air handling unit (AHU) system is a mandatory requirement for many industries such as pharmaceuticals, food processing, electronics, and artifact storage. In practice, humidity measurement deviations occur quite frequently, directly affecting product quality, operating costs, and environmental control performance.

Common Causes of Humidity Deviations in AHU

Common causes include humidity sensors becoming contaminated with dust, aging over time, or being installed in improper locations. Many systems still use older-generation sensors without temperature compensation, causing measurement drift when environmental conditions change.

An appropriate solution is to use humidity sensors specifically designed for AHU applications, such as wall-mounted sensors, duct-mounted sensors, or sensors with integrated temperature measurement. Sensor lines in EMIN’s portfolio from brands such as Senseca, EZDO, and Dwyer are designed for HVAC systems, perform reliably under high humidity and continuously fluctuating temperatures, and are suitable for long-term operation.

Another frequently overlooked cause is the lack of periodic calibration. Many facilities stop at cleaning the probe surface without re-verifying the measured values. In such cases, using a reference humidity generator or a mini calibration chamber helps systematically evaluate and correct deviations, reducing the risk of recurring measurement errors.

In addition to direct measurement sensors, pharmaceutical and food factories operating under GMP, electronics facilities, or museums may supplement their systems with temperature and humidity data loggers to continuously monitor conditions within the AHU air duct. Devices such as the HUATO S500-TH allow storage of measurement history, support early detection of value drift, and enable timely corrective actions.

Read more:

How to check humidity to prevent hay and straw from overheating and deteriorating

Why is material moisture measurement important in construction and industry?

How to check humidity to prevent paper from warping and deteriorating

5-Step Procedure for Handling Humidity Deviations in AHU

Step 1: Inspect and clean the sensor

Before performing any work, disconnect the AHU power supply to ensure safety. Check signal cables, connectors, and the physical condition of the sensor. When cleaning the probe, use a soft brush or a dedicated cleaning solution as recommended by the manufacturer; avoid using water or strong chemicals unless specifically instructed.

Step 2: Compare on-site measurement values

Use a handheld temperature and humidity meter with recent calibration, and place its probe near the AHU sensor within the same airflow. Compare the two readings to determine the deviation. If the difference exceeds the sensor’s allowable tolerance (typically ±3% RH), further evaluation of related factors is required.

Step 3: Recheck the installation location

The sensor should be installed at a location representative of the airflow to be controlled, avoiding proximity to heating coils, water valves, direct fan discharge, or large metal surfaces. A straight duct section with stable and uniform airflow is always the preferred option.

Step 4: Perform in-depth calibration

If cleaning and repositioning do not yield the desired results, recalibration is necessary. A humidity calibration kit can be used to create a reference environment on site, or the device can be sent to a professional calibration laboratory to ensure compliance with technical requirements and quality management standards.

Step 5: Replace when necessary

For sensors that have deteriorated, are damaged, or no longer meet requirements after multiple calibrations, replacement is a reasonable option. Using sensors specifically designed for HVAC and cleanroom applications helps reduce operational risks and optimize long-term maintenance costs.

Conclusion:

Addressing humidity deviations in AHU systems requires a clear and systematic process, from inspection and comparison to calibration and replacement when necessary. Proper application of the steps above helps ensure stable AHU operation, compliance with environmental control requirements, and adherence to current technical standards.

For consultation on selecting humidity sensors, data loggers, or suitable calibration services for AHU systems, you may contact EMIN directly for detailed support.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-