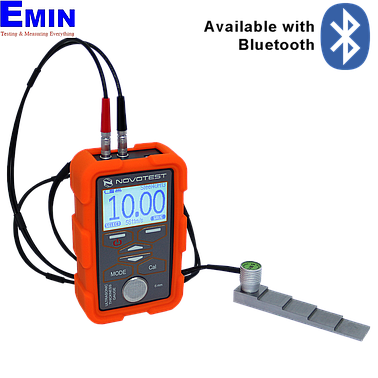

NOVOTEST UT-1M Ultrasonic Thickness Gauge

Manufacturer: NOVOTEST Model: UT-1M Guarantee: 12 Month - Request a Quotation

- Request a Quotation

Price (exclude Commercial Tax) 3,840,000 Kyat Price (include Commercial Tax) 4,032,000 Kyat

Thickness measurement range (0,8 – 1000mm)

Customer gain control

Possibility to make V-correction of the transducer

Shock-resistant housing

Allows to save probe settings

Sound gain up to 20 dB

Specification

Measuring thicknesses range , mm: 0.8 ... 300

Probe 10MHz – P112-10-6 / 2: (range 0.8-30mm)

Probe 5MHz – P112-5-10 / 2: (range 1-75mm)

Probe 2,5MHz – P112-2,5-12 / 2: (range 2-300mm)

Setting range of the ultrasonic velocity, m / s: 1000-9999

Discrete readings on the digital indicator,mm: 0.1

Response time, with no more than, s: 2

Basic measurement accuracy, mm: ± (0,001 T+/- 0.1)

Overall dimensions, mm :120x60x25

Operating temperature range, ° C: -5 to +40

Power supply: 2 AA batteries

Time of continuous work hours, not less, h: 10

Weight of electronic unit with battery, no more, kg: 0.2

Standard set:

Electronic unit Ultrasonic Thickness Gauge

Transducer (probe) – 1 pc (depends on the desired range of controlled thickness)

2 AA batteries

Charger

Cables

Calibration certificate

Operating manual

Case

Available options:

Couplant; UT-probes; Calibration blocks

- Echo-Echo (Through-Coating) probe for NOVOTEST UT-1M (-IP, -ST, -2A)

- High-temperature probe (up to 250°C) for NOVOTEST UT-1M (-IP, -ST, -2A)

Description:

- Ultrasonic Thickness Gauge NOVOTEST UT-1M is used for operational non-destructive testing of the thickness of products with one-way access, at the moment this method is the most common in the world for solving such tasks.

- The method is based on the property of materials to conduct ultrasound, ultrasonic wawes are excited with the piezoceramic plate in the transducer and penetrates into the material through the couplant, then reflected from the bottom surface of the tested sample, and returns to the transducer. Based on the obtained sound transit time in the material, the device calculates the thickness in accordance with the velocity of propagation of ultrasonic waves in the test sample. The thickness value is displayed on the device’s display, the measurement process takes about 1 second.

Advantages:

Wide range of measuring thicknesses

- Convenience and ease in operation

- Minimum number of controls

- Select the type of probe through single button

- Preset velocity of ultrasound

- Graphical display with backlight

- Compensation of probe delay

- Control of the batteries

- Mapping the presence of acoustic coupling on the graphic display

- Fixation of the last measurement result in the removal of the transducer surface

Datasheet

- Quality Engagement

- Easy change and return

- Delivery Avaliable

- Favorable payment