Explain the cause of starting from no suction, what is the solution?

When it comes to types of equipment that serve consumer needs, induction starter is one of the outstanding product lines with eye-catching design and quite easy installation. However, during use, this device may encounter some problems that need to be fixed immediately to ensure smooth, stable operation and better efficiency. In particular, there will be the phenomenon of starting from no suction, this is also a common problem that many users often encounter. This article will help you understand the causes and provide specific solutions to handle this situation.

Contents

What is a starter?

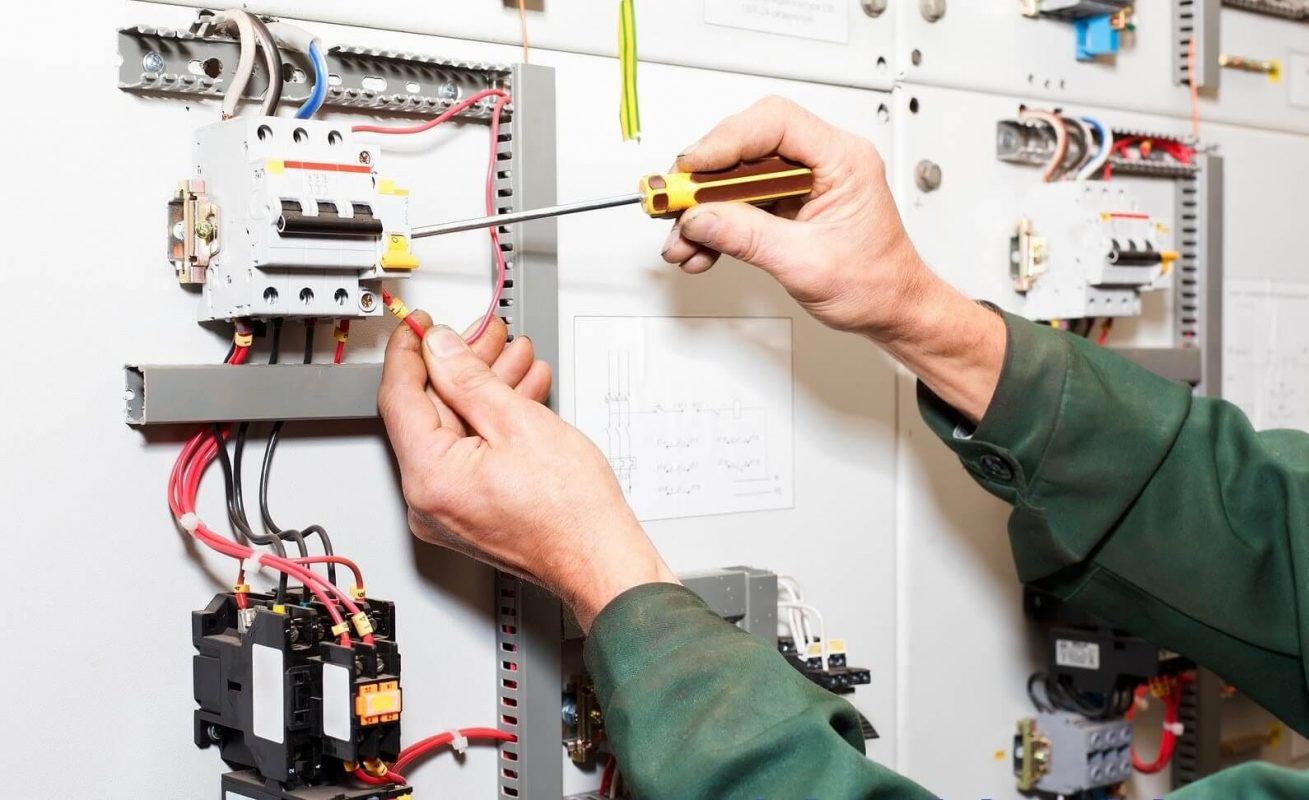

Surely you already know that magnetic starters are a popular device in many industries today thanks to their flexibility and ease of installation in electrical cabinets or electrical panels. Good connectivity with other devices and high stability make it a considered choice for users in power systems. With remote shutdown function and protection against electrical overload, magnetic starters play an indispensable role in the electrical systems of factories or workshops. However, when something goes wrong, repairing this device is not always simple. So what causes the problem and how to fix it?

Magnetic power supply is interrupted

The power supply plays a role in ensuring optimal starting operation, meeting the needs of the user. Therefore, manufacturers always pay attention to the quality of the power supply for this device. When the power supply has a problem, the magnetic starter can operate slowly, unstable and difficult to control opening and closing. At this time, the user needs to check whether there are any obstructions on the power supply side, and ensure that the input current matches the required capacity of the device.

Another cause of power supply interruption may be that you do not regularly check and maintain the device, leading to unstable power supply, reducing the performance of the magnetic starter. To fix it, you should choose a more suitable installation location, periodically check the power supply at EMIN to ensure a stable current, helping to start the operation more quickly and effectively.

Damage to control buttons during use

Việc sử dụng sai cách có thể khiến nút nhấn hỏng, gây phiền toái trong quá trình hoạt động của thiết bị. Để tránh tình trạng này, bạn nên nhẹ nhàImproper use can cause the button to break, causing inconvenience during device operation. To avoid this situation, you should be gentle when operating and do not press too hard on the control button. In case the push button is broken, you need to disconnect the power source from the starter, then use protective tools to check and adjust. If the damage is too serious, replacing the button will be the best solution.

When operating, do not press too hard on the control button. In case the push button is broken, you need to disconnect the power source from the starter, then use protective tools to check and adjust. If the damage is too serious, replacing the button will be the best solution.

Contacts are rusty due to long-term use

Contacts may rust after a long period of use, affecting the device's performance. To fix this problem, you need to carefully check the rust level before replacing. Use testing equipment to determine whether the contact is still energized or not, then use support tools to disassemble and replace with a new contact. Timely replacement will help start-up and operate more stably and efficiently, ensuring the electrical system operates smoothly.

Stuck while in use

When the device shows signs of jamming, see if there is a strange sound during connection, or consider whether there is a problem with the power cord or other electrical devices in the system. After determining the cause, it is necessary to adjust the connections accordingly.

What to note when using magnetic starter

- First of all, avoid long-term continuous use to avoid disruption to the device.

- Installation also needs to be done in appropriate locations, avoiding environments with too high or too hot temperatures, as this may affect performance.

- lacing the device in an electrical cabinet is a good choice to ensure safe and effective connection.