Rational

Rational Precision Instrument Co., Ltd. – Geometric Measuring Solutions for Manufacturing and Quality Control

Overview of Rational Precision Instrument Co., Ltd.

Rational Precision Instrument Co., Ltd. is a company specializing in the development and manufacturing of precision measuring instruments in the fields of mechanical and optical measurement, serving the inspection of dimensions, shapes, and geometric tolerances of technical components. The company originated from a research foundation in Taiwan and has focused its development on measurement solutions for industrial manufacturing.

Unlike manufacturers offering a wide range of measurement technologies, Rational follows a focused approach in geometric measurement, non-contact measurement, and optical measurement, meeting the increasingly stringent requirements of precision machining, mold manufacturing, and quality control.

Rational’s Role in the Manufacturing Quality Control Chain

In modern manufacturing environments, dimensional and shape inspection is no longer limited to final inspection but is applied throughout the entire production process. Rational’s instruments are commonly used for:

Inspecting profiles and geometric deviations after machining

Measuring small, complex parts or sensitive surfaces

Evaluating machining accuracy during production

Supporting tool setup and inspection before operation

Rational’s measurement solutions help manufacturers maintain stable quality control, reduce defects, and improve the reliability of finished products.

Product Portfolio of Rational Precision Instrument Co., Ltd.

Profile Projectors: These instruments are used to measure and compare the shape and profile of mechanical parts through optical projection. They support the inspection of dimensions, angles, radii, and geometric deviations, making them suitable for mold making and precision machining.

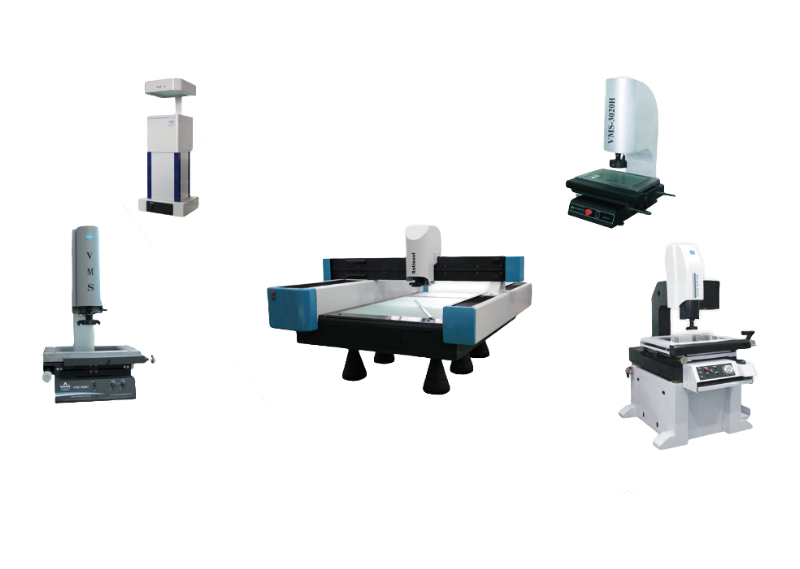

Video Measuring Systems: Video measuring systems enable non-contact measurement based on optical imaging, allowing accurate evaluation of part dimensions and shapes. This product group is well suited for small, complex parts or applications where mechanical contact should be minimized.

Coordinate Measuring Systems: Coordinate measuring systems support the inspection of position, geometry, and spatial deviations of mechanical components. These solutions are widely used in quality inspection and machining accuracy evaluation in industrial production.

Tool Microscopes and Metallurgical Microscopes: This category is used for observing and analyzing surfaces and material structures at high magnification. The instruments are applied in the inspection of cutting tools, mechanical components, and surface quality evaluation.

Height Measuring Instruments: Height measuring instruments are used to accurately determine height dimensions and vertical deviations of parts. They are commonly applied in machining workshops and inspection rooms.

Tool Preset and Tool Inspection Instruments: This product group supports the measurement and presetting of cutting tools before machining, helping reduce errors, shorten setup time, and improve production efficiency.

Linear Scales and Digital Readouts: These devices capture and display measurement positions, enhancing accuracy in machinery and mechanical measurement systems. They are often integrated into complete measurement solutions.

Measurement Software and Supporting Systems: Measurement software processes data, analyzes results, and manages measurement information, helping users optimize inspection workflows and quality evaluation.

Value Rational Delivers to Manufacturing Enterprises

Rational does not position itself as a general-purpose brand, but instead focuses on solving the core challenges of precision manufacturing: accurate measurement, stable performance, and practical application in real operating environments. With this focus, Rational’s instruments effectively meet the needs of geometric inspection in environments requiring high precision and repeatability.