I.C.T

Manufacturer Information

I.C.T – Manufacturer of SMT Equipment for Modern Electronic Assembly Lines

Introduction to I.C.T

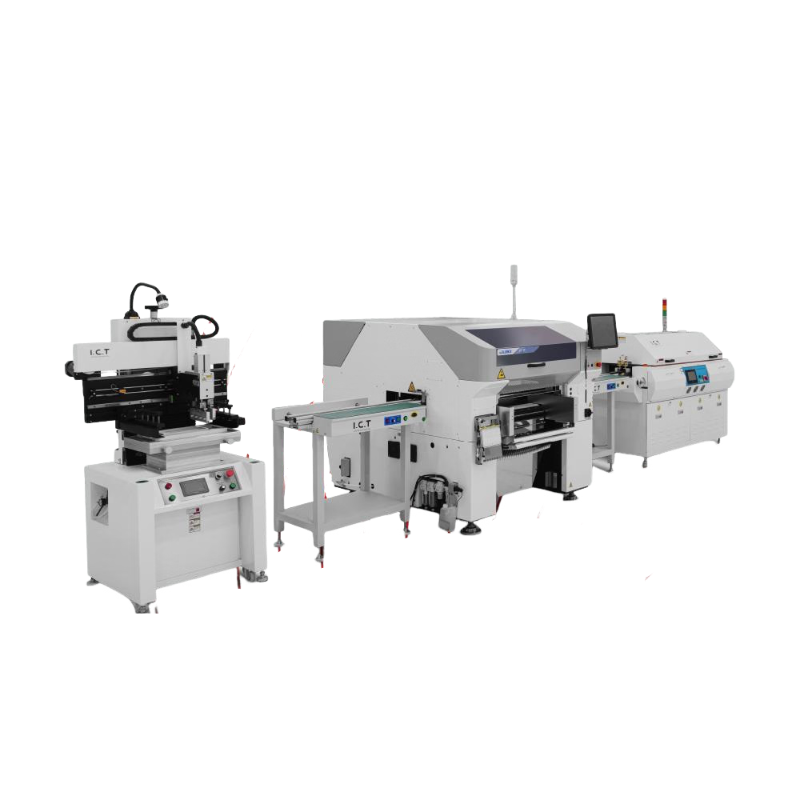

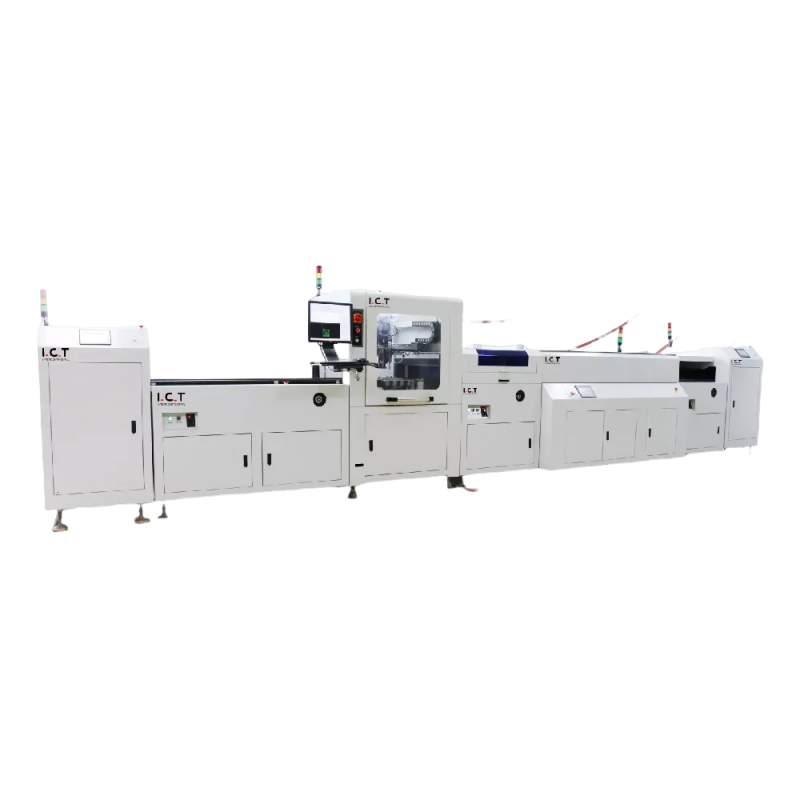

I.C.T is a manufacturer of SMT equipment and electronic assembly support equipment, focusing on developing integrated solutions for PCB/PCBA production lines. Built on many years of experience in the SMT industry, the company emphasizes standardizing electronic assembly processes while improving accuracy and operational stability in industrial manufacturing.

With independent research and manufacturing capabilities and a diverse equipment ecosystem, I.C.T has gradually strengthened its position in the SMT equipment sector. Its solutions support production lines ranging from semi-automatic to highly automated systems, suitable for various scales of electronic manufacturing facilities.

Development Orientation and Core Strengths of I.C.T

I.C.T focuses on developing equipment aimed at optimizing production efficiency and ensuring line-level integration, helping manufacturers to:

Standardize each stage of the PCB/PCBA assembly process

Reduce deviations during component placement and soldering

Enhance stability during continuous operation

Easily expand or integrate production lines in the future

The company’s equipment is widely applied in consumer electronics, LED manufacturing, telecommunications, industrial electronics, and other applications requiring high precision and reliability.

SMT Equipment Categories of I.C.T

SMT Component Placement Equipment: This group of equipment performs the placement of electronic components onto PCB boards using SMT technology, ensuring high accuracy, stable speed, and the ability to handle a wide variety of components in electronic manufacturing.

Solder Paste Printing Equipment: Designed for printing solder paste onto PCB surfaces prior to component placement, this equipment plays a critical role in solder joint quality and overall SMT process stability.

SMT Soldering Equipment: Includes equipment that carries out the soldering process through controlled temperature and timing, helping achieve strong, uniform solder joints while minimizing production defects.

Inspection and Quality Control Equipment: Supports the detection of assembly errors, solder paste defects, and component misalignment during and after production, improving yield rates and reducing rework costs.

PCB Handling and Conveying Equipment: Responsible for transporting, loading, unloading, and handling PCB boards within SMT production lines, ensuring smooth workflow and reduced manual intervention.

SMT Cleaning and Auxiliary Equipment: Serves cleaning processes for PCBs and components, as well as auxiliary material handling, contributing to higher product reliability and longer service life.

PCB Cutting and Depaneling Equipment: Supports cutting and separating PCB boards after production according to technical requirements, ensuring mechanical precision and component safety.

The Role of I.C.T Equipment in Electronic Manufacturing Lines

I.C.T’s SMT equipment system helps establish a fully integrated electronic assembly line, where each process is designed to complement the others. As a result, manufacturers can:

Maintain better control over product quality

Reduce reliance on manual operations

Improve stability in high-volume production

Standardize processes in line with factory requirements

These factors are increasingly important as electronic manufacturing demands higher accuracy and consistency.

Conclusion

I.C.T is a solution-oriented SMT equipment manufacturer focused on building a complete electronic assembly equipment ecosystem for modern PCB/PCBA production lines. With equipment covering the entire SMT process, the company effectively supports manufacturers in optimizing production, improving quality, and moving toward sustainable automation in the electronics industry.

Get exclusive volume discounts, bulk pricing updates, and new product alerts delivered directly to your inbox.

By subscribing, you agree to our Terms of Service and Privacy Policy.

Direct access to our certified experts