Some notes that are easily overlooked when measuring dew point temperature

Dew point temperature is an important indicator that helps control humidity, protect equipment and maintain a safe living and production environment. This article will guide you through the necessary notes when measuring dew point temperature, helping you understand the role of dew point measuring devices, how to use them effectively, common errors and how to fix them. Let's learn about practical examples of the application of temperature, humidity and dew point measuring devices in life and production!

Contents

I. What is dew point temperature?

Concept of dew point temperature

The dew point temperature is the temperature at which the air becomes saturated with water vapor and begins to condense into dew. In the early morning, you may see water droplets on your car's windshield or windows. This is when the surface temperature of the glass is lower than or equal to the dew point temperature of the surrounding air.

The importance of measuring dew point temperature

Protecting electronic equipment and machinery: High humidity exceeding the dew point can cause water condensation, damaging electronic components or rusting machinery.

Production quality control: In industries such as paint, food, pharmaceuticals, controlling the dew point helps ensure that products are not affected by humidity. In paint factories, if the dew point is not well controlled, the paint layer can peel off due to condensation on the surface of the material before painting.

Health protection: High humidity and low dew point are favorable conditions for mold growth, affecting human health.

Why do we need to measure dew point temperature?

The dew point temperature is the temperature at which water vapor in the air begins to condense into water droplets. Measuring this parameter is especially important in areas that require humidity and condensation control, such as warehouse storage, electronics manufacturing, HVAC system operation, or industries that require dry environments such as pharmaceuticals and food.

If the dew point temperature is not well monitored and controlled, moisture can condense on equipment surfaces, causing corrosion, component damage, or even interrupting the entire production process. Therefore, measuring the dew point temperature not only helps maintain product quality, but also protects the system and minimizes operational risks.

II. Important notes when measuring dew point temperature

1. Choose the right dew point thermometer

Use a dedicated measuring device: You should choose a temperature, humidity, dew point measuring device with high accuracy, the ability to warn when exceeding the threshold such as EXTECH 445815, which helps to display temperature, humidity and dew point simultaneously on a large screen, with audio and visual warnings when exceeding the set threshold.

Check the measuring range: Make sure the device has a measuring range suitable for the environment of use, for example: measuring range from -10°C to 60°C and humidity from 10% to 99% RH.

Choose the right sensor: Modern sensors allow fast, accurate measurements, can be used indoors or outdoors. When checking cold storage, you need a measuring device with a flexible probe to measure in hard-to-reach locations such as the corner of the cabinet or behind the shelf.

2. Correct procedure for measuring dew point temperature

Place the device in a representative location: Place the device at the location to be tested, away from direct heat or steam sources so that the results accurately reflect the general environment. In the laboratory, technicians often place the measuring device in the center of the room, away from the door to avoid the impact of air flow from the outside.

Wait for the device to stabilize: After placing the device, wait a few minutes for the sensor to adapt to the environment, giving accurate results.

Read and record data: Record the dew point temperature, ambient temperature and humidity at the time of measurement. Some devices also save the maximum and minimum values to help track fluctuations.

3. Common errors and how to fix them when measuring dew point temperature

Place the device in an inappropriate location: Placing it near a window, fan, or air conditioner will distort the results. It should be placed in a place that is not directly affected by heat or wind sources.

Not calibrating the device: If the measuring device is not calibrated for a long time, it will give inaccurate results. It is recommended to check and calibrate it periodically according to the manufacturer's recommendations.

Not paying attention to environmental conditions: Too high or too low humidity can affect the sensor. Avoid exposing the device to water or dust. Some factories place the measuring device right next to the entrance, causing the dew point temperature measurement results to not reflect the actual conditions in the production area.

Read more:

What is the fastest and most convenient method to measure dew point temperature?

There are several ways to determine the dew point temperature of compressed air

III. Practical applications of dew point temperature measurement

- In industry and manufacturing

Paint and construction industry: Measuring dew point temperature helps determine the right time to apply paint, avoiding peeling or mold due to condensation on the surface of the material.

Food and pharmaceutical industry: Controlling dew point temperature helps preserve products, avoiding damage due to high humidity.

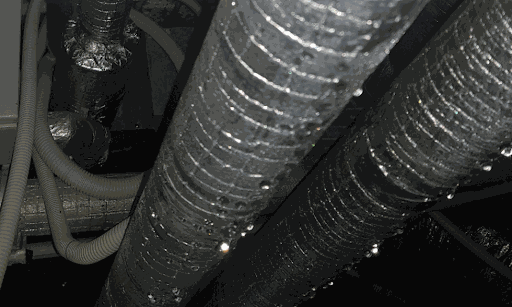

HVAC system: Ensures air conditioning operates effectively, avoiding condensation on glass doors and walls.

- During the maintenance of central air conditioning systems, technicians use dew point meters to determine locations at risk of condensation, thereby adjusting the system promptly.

- In daily life

Controlling humidity in the house: Measuring dew point temperature helps detect mold risk early, protecting family health. In particular, families with young children should regularly check dew point temperature to adjust the dehumidifier, ensuring a dry and safe living environment.

Preserving electronic devices: Especially in the humid season, measuring dew point helps determine whether the environment is safe for electronic devices or not.